What is industrial machinery?

Industrial machines are tools that apply advanced and modern technologies of the world. Thanks to those designs, the ability to create items is much stronger and more efficient. Currently, almost all industries are using modern technology-applied machinery.

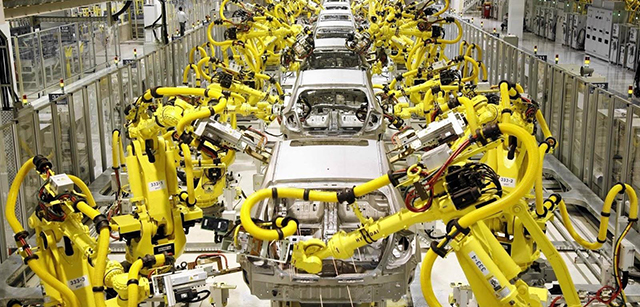

Most industries put machines into production

Not only in industry, but also in agriculture, machinery is put into use. Thus, promoting economic development as well as improving labor productivity.

The importance of industrial machinery and equipment in life

Today, industrial machinery not only serves industry but participates in many areas of modern life. Needless to say, many people know that this machine plays an extremely important role in life.

Most machines are invented with the purpose of supporting human work to happen quickly. With the help of machines, human labor will be liberated. Machines are capable of doing detailed work even to the difficult and dangerous stages. Besides, today there are machines that do multiple jobs at the same time. Even the difficult positions that only human power can't change a thing.

It helps people a lot in difficult jobs

Modern life always requires fast and efficient work. Therefore, regardless of working in any field, machines still ensure work efficiency. Users only need to learn and choose the right type of machine needed for the industry they are doing. Then you will find the device that is both modern and most suitable.

You can rest assured that all industrial equipments are manufactured on modern production lines. Every part on the machine is made scientifically and precisely. No need for too much support in human strength, but the product quality is always good. One of the industries that need a lot of machines is the food industry. Smart devices have become an integral part of businesses.

The outstanding advantages of industrial equipment

Each industry will have production machines suitable for specific industries. And each of those devices has its own outstanding advantages.

- Save more time than manual labor. Thus, operational productivity is improved, bringing profits to the business.

- Using machines applying advanced technology should attract the attention of large investors.

With just a few simple steps, you can make the machine work quickly

- When working, the machine can operate continuously without interruption. As a result, labor productivity increased dramatically.

- Help businesses save a cost of hiring labor. With a good number of machines, it will only need a number of skilled workers to operate the machines.

- The application of machinery in production will reduce production costs. The quality of the product is higher, and the output price of the product is lower. Helps a lot to compete with brands in the same field.

- Using industrial equipment in product processing will make the product more even and beautiful.

- Equipment cost is also suitable because the equipment is processed in series.

- Help people with jobs that cannot be handled by manual methods. For example, tapping materials, drilling on steel, cutting details for machines...

Industrial machines for production needs

Today, industrial machines are divided into four groups for human purposes. Besides, there are also equipment to meet diverse needs of use in many different fields. But basically the devices are divided into 5 dedicated groups to serve different purposes.

In advanced countries machines are involved from start to finish in the production of products

Industrial machinery and equipment for the mechanical industry

First, these machines fulfill the needs of the mechanical engineering group. Most of them are mechanical processing machines that help users. Some equipment can be mentioned such as: iron cutting machine, milling machine, lathe, drilling machine, metal detector, welding machine... Using these machines will make mining work easy. Productivity or work efficiency is improved.

Imagine that without the support of machines, workers would lose a lot of time and effort. Especially dangerous jobs such as mining must often work in the mines. Modern machinery and equipment will greatly improve the work. For mine workers, it will be less tiring, safer and reduce occupational accidents.

Equipment that generates great pressure

With machines that generate great pressure, users can completely choose from the following types: pipe bending machines, presses, thread rolling machines, casting machines... Not only that, there are also furniture assembly equipment. . Users can consider investing to support their work such as modules, desk clusters...

Drinking machines and presses will reduce human hardship

Depending on the characteristics of each industry, there will be suitable equipment for the needs. In the plastic industry will need plastic molding machines, plastic injection machines. Also producing canned food or food needs a vacuum machine. Only then can we rely on high pressure to pack as well as preserve products.

Industrial cleaning machinery

To meet the market demand, industrial equipment is applied in the field of hygiene. For large areas such as factories or industrial zones, traditional methods cannot be guaranteed. Because then the cleaning staff will spend a lot of time performing the job continuously. This both consumes effort to clean and brings low efficiency.

However, when there was the advent of industrial hygiene equipment such as the right arm to help solve all problems. The cleaning machines can be mentioned as: large capacity vacuum cleaner, car wash machine, floor scrubber ... With the help of these products, businesses can save a lot of labor costs. Moreover, the cleaning efficiency is high and fast.

In large spaces, industrial cleaning equipment is indispensable

Currently on the market there are many models with different capacity. Therefore, based on the needs of use, people can consider choosing the right product.

Machines doing maintenance work

Long-term operation of equipment and production lines is prone to problems. Want those machines to work durable, minimize the damage that occurs. Must regularly check, clean and carry out routine maintenance steps. At such times, there is a need for machinery to support maintenance work. One of the outstanding products to mention is the specialized grease pump .

With this device, people can grease engines and machines at any time, which is extremely convenient. The accessories that come with the grease pump are all flexible types that help a lot for maintenance. Particularly for the grease pump head, there are many types to ensure that the grease can go to small details that are invisible to the naked eye.

If you want to maintain machines and engines, you really need a compact - handy grease pump

Today, there are many different types of grease pumps for people to choose from. These can be mentioned as: air compressor grease pump, manual - foot grease pump, electric grease pump... There are also many famous grease pump brands on the market such as: Palada grease pump , Masada grease pump . , …

Some small equipment used in industry

Besides large industrial equipment, there are also portable machines. They are extremely compact with a small weight of less than 1kg even only a few hundred grams. Those machines have an extremely important role often used in technical inspection. There are a number of types of electricity meters, heat meters, pressure gauges, etc.

They are all necessary for industries, especially those requiring high accuracy. Requires all elements of pressure or temperature to be absolutely accurate to each number. That said, it is necessary to rely on the use of each machine to combine and research the quality of the machine to ensure the best quality product.

Just a small device but guarantees absolute accuracy

The more inventions of industrial machines with a variety of capacities and types, will bring customers good products. They are good both in terms of cost as well as time of use.

When to maintain industrial machinery?

Machines used for a long time without regular maintenance are prone to breakdowns. Once broken, the cost of repairing industrial machinery is very expensive. Even many of them had to be abandoned because of too much damage. Therefore, it is necessary to check and change the oil regularly for equipment and components to operate effectively. But when to need maintenance is a question that many people care about.

The time of machine maintenance depends a lot on the climate, equipment storage environment, ... At the same time, the way the business operates also greatly affects the time of maintenance. There are many types of machines that have timelines and standards for determining maintenance intervals.

Usually the time of maintenance is after 12 months of use. There are also machine lines that require maintenance after 5,000 working hours. These requirements are based on actual tests, operability.

Regular machine maintenance is the best way to prolong product life

However, the first time the new machinery system is installed, the maintenance time is quite short. And after a period of use, the maintenance period falls from 12 months to 1 year. That way to ensure that errors can be detected and promptly corrected during use.

Things to note when installing industrial machinery and equipment

In order to import equipment, enterprises have to pay a rather high import tax on industrial machinery and equipment. And those costs are calculated when you buy any industrial product. Therefore, the cost of products will often be high, so when installing machines, it is necessary to pay attention to the following:

- Quality of the device

Surely everyone knows that industrial equipment is the decisive factor for the success of a production line. Because those machines are directly involved in all production processes. It is also the first factor that determines the quality of the product.

When the equipment is made from good quality, it will minimize the damage that occurs on the machine. The selection of good quality machinery will also save a lot of costs for maintenance and repair.

During the installation process, skilled engineers must always follow closely to ensure safety

- Ensure safety during installation

The next factor that needs attention is that in the process of installing machinery, safety must always be a top priority. So installation engineers must plan specifically to ensure the whole process meets all safety standards in the industry. This helps to minimize labor accidents as well as production losses.

- Efficiency of machines

When investing in machinery, you have to spend a large amount of money because now the cost of products is high. With a production line system, it also costs several hundred million. Not only that, the operation process will also cost to maintain machines and production lines. Therefore, it is necessary to choose a device that saves fuel but still has high efficiency. At the same time, consuming less fuel will also reduce production costs.